Extending the life of industrial blades is crucial for maintaining efficiency and reducing operational costs. Industrial cutting blades are used in various applications, such as cutting, shredding, or processing materials. Here are some tips to help you extend the life of industrial cutting blades:

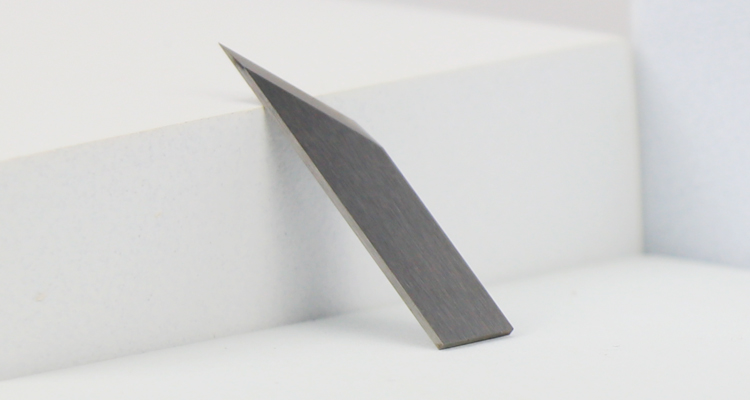

Proper Blade Selection:

Choose industrial cutting blades designed specifically for materials and applications. Hardness, tooth configuration and coating are considered according to the nature of the cutting task.

Regular Maintenance:

Perform regular maintenance schedule to inspect and maintain cutting blades.

Check for signs of wear, damage or dislocation and deal with the problem in a timely manner.

Lubrication:

Employ suitable lubrication techniques to minimize both friction and heat while operating.

Adhere to the manufacturer's advice as certain industrial cutting blades might need particular lubricants.

Cooling Systems:

Install cooling systems if necessary to dissipate heat generated during cutting operations.

Heat can accelerate blade wear, and cooling systems help maintain optimal operating temperatures.

Proper Alignment:

Ensure that the blades are properly aligned to prevent uneven wear.

Misaligned cutting blades can lead to increased stress on specific areas, causing premature wear.

Precision Grinding:

Implement precision grinding to maintain the sharpness and cutting edge of the blades.

Regularly grind blades to remove any nicks or dull spots.

Balancing:

Balance industrial cutting blades to prevent excessive vibration during operation.

Vibration can contribute to premature wear and may affect the overall performance of the machine.

Correct Cutting Technique:

Train operators on proper cutting techniques to avoid unnecessary stress on the industrial cutting blades.

Improper cutting techniques can lead to increased wear and damage.

Material Inspections:

Inspect the materials being processed for any contaminants that could damage the industrial cutting blades.

Remove any foreign objects before they come into contact with the blades.

Storage:

Store industrial cutting blades in a clean, dry environment to prevent corrosion.

Use appropriate covers or cases to protect the blades when not in use.

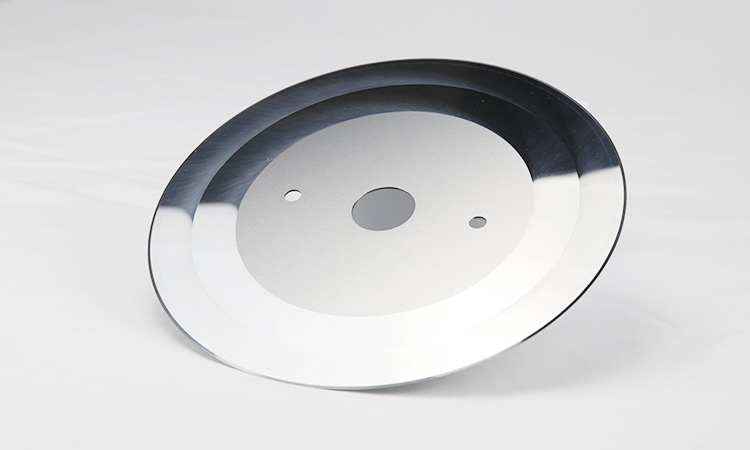

Quality Blades:

Invest in high-quality industrial cutting blades from reputable manufacturers.

Quality blades are often made from durable materials and undergo precise manufacturing processes.

Regular Sharpening:

Develop a regular sharpening schedule based on the usage and material being processed.

Follow the manufacturer's recommendations for sharpening frequency.

Always refer to the manufacturer's guidelines and recommendations for specific industrial blades, as they may have unique requirements and specifications for care and maintenance. Regular monitoring and proactive maintenance are key to extending the life of industrial blades and ensuring optimal performance.

Post time: Jan-31-2024