1. High-speed steel blade, is one of the common cutter blade materials, compared with other materials, high-speed steel blade has a lower price, easy to process, high strength and other advantages. HSS blades can be used in different shapes and sizes to meet different cutting requirements. In the machining process, in order to give full play to the performance and improve the service life of HSS blades, it is necessary to reasonably select the cutting parameters and tool geometry, and carry out correct sharpening and maintenance. However, when cutting high hardness and high strength materials, the wear resistance and hardness of HSS blades cannot meet the requirements.

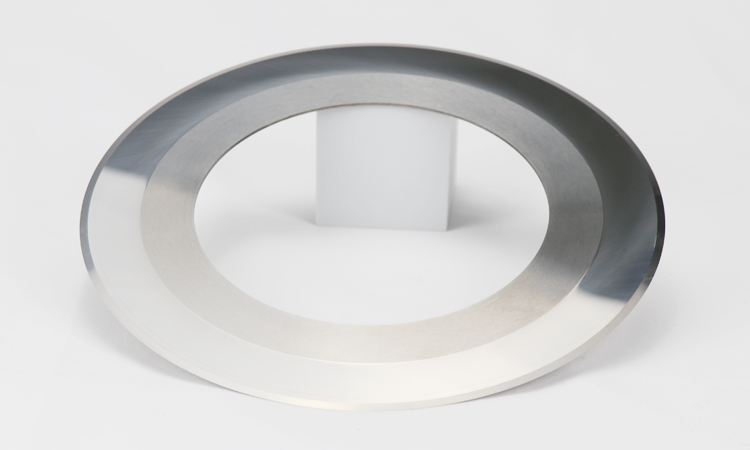

2. Tungsten carbide blade, whose main components are tungsten carbide and cobalt, are made by powder metallurgy process. It has excellent characteristics such as high hardness, high wear resistance, high strength and good toughness, which can maintain stable cutting performance and long service life under high temperature and harsh cutting conditions. Tungsten carbide blades are refined through a number of production processes, and their base is made of integral tungsten carbide, which is processed through precise cutting and grinding processes. During the machining process, the edges of the tungsten carbide blades can be machined into various shapes and sizes to meet the requirements of different cutting tasks.

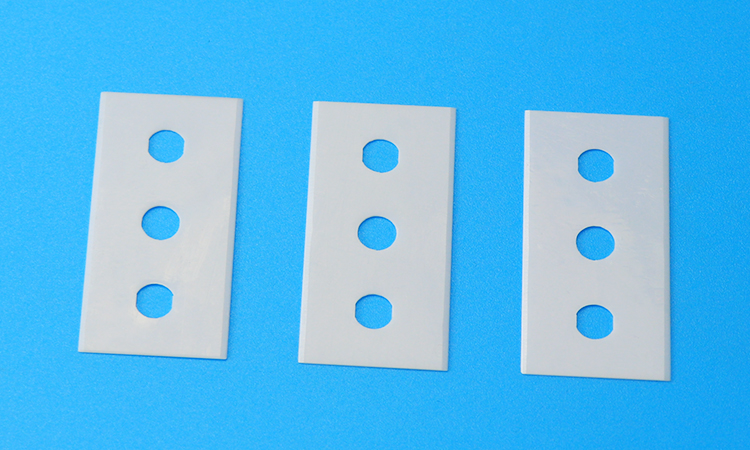

3. Ceramic blade, a new type of cutting tools, are made of high-purity ceramic materials such as zirconia and alumina, whose hardness is second only to diamond, with very high hardness and wear resistance, and they are widely used in the field of high-precision and high-demanding metal cutting and machining. Compared with traditional blade materials, ceramic blades have higher cutting efficiency, longer life and lower cutting force after precision machining and special treatment, which is considered to be the future development trend of metal cutting processing.

Post time: Feb-20-2024