How to Select the Perfect Machine Knives and Blades for Various CNC Machines.

In the competitive landscape of CNC machining, the choice of machine knives and blades goes beyond mere technical specifications. It's about understanding the complex requirements of different machines and the materials they are tasked to shape or cut. For CNC blade dealers, this understanding is crucial in matching blades with multiple machine brands, ensuring optimal performance and customer satisfaction.

When choosing machine knives and blades for CNC machines, it's essential to consider the material to be cut, blade durability, and compatibility with diverse machine brands. A supplier's in-depth knowledge about various CNC machines significantly influences the quality and performance of the tools you offer.

Now, let's explore the critical factors that ensure you make informed selections for your inventory.

Material Matters: Selecting the Right Blade Material

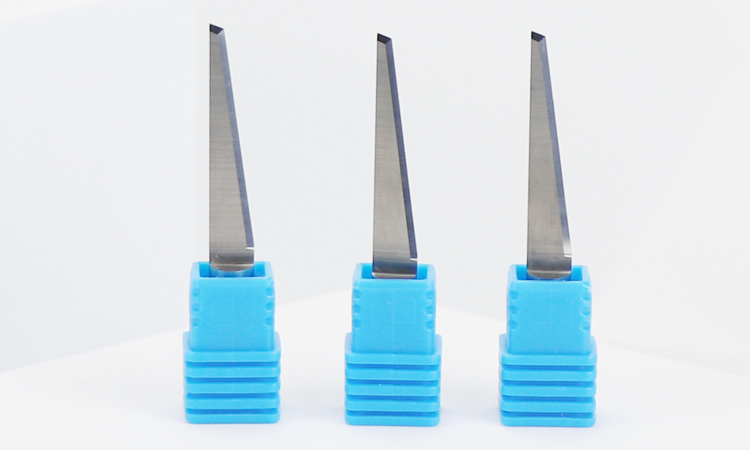

Choosing the correct material for CNC machine blades and knives is paramount. The right material affects the tool's durability, cutting efficiency, and longevity. Typically, materials like carbide, high-speed steel (HSS), and tool steel are popular due to their hardness and resistance to wear. Each material suits different cutting tasks: carbide for high-volume production due to its hardness, HSS for its toughness in unpredictable conditions, and tool steel for its cost-effectiveness and ease of sharpening.

Compatibility with CNC Machine Brands: A Supplier's Perspective

One critical aspect often overlooked by dealers is the supplier's awareness of various CNC machine brands. This knowledge is not just about ensuring the physical fit of a blade or knife but about understanding how a particular tool's design and material complement the machine's capabilities. For example, some blades are specifically designed for high-speed machines, while others perform better under low-speed, high-torque conditions. Partnering with a supplier who understands these nuances can make a significant difference in the performance and satisfaction levels among your clients.

Maintenance and Longevity: Tips for Keeping Blades Sharp

The longevity of machine knives and blades not only depends on the material and compatibility with CNC machines but also on proper maintenance. Regular inspections for wear and damage, timely sharpening, and correct storage practices can extend the life of CNC blades significantly. Educating your clients on these maintenance practices can help them get the most out of their purchases, reducing the frequency of replacements and enhancing their overall operational efficiency.

In conclusion, the selection of machine knives and blades for CNC machines requires a deep dive into the materials used, an understanding of the specific requirements of different CNC machine brands, and a commitment to maintenance for longevity. By ensuring your supplier is well-versed in the diversity of the CNC machining industry, you position yourself as a go-to resource for high-quality, compatible tools that meet the varied needs of your clients. Partnering with a knowledgeable supplier not only enhances the performance of the tools you offer but also builds trust and reliability among your clientele.

Post time: Mar-14-2024