Step 1:

Dismount the complete set of grinding stone Mount the new grinding stone

Step 2:

Take out the worn out blade and mount the new slitting blade.

Step 3:

Install back the grinding stone set, disconnect the air supply on the air cylinder for grinding stone to insure there is no pressure applied on the grinding stone.

Step 4:

Hand push the two shafts on the air cylinder to allow the grinding stone to touch/kiss the knife edge on both sides.

Step 5:

Use wrench to make sure the grinding stone set and knife edges(both sides) are kissing touched. Hand turning the grinding stone to check the contact frication between both grinding stones and knife edges are literally the same frication (not one stone tight, one stone loose.). Then tight the screws and nuts.

Step 6:

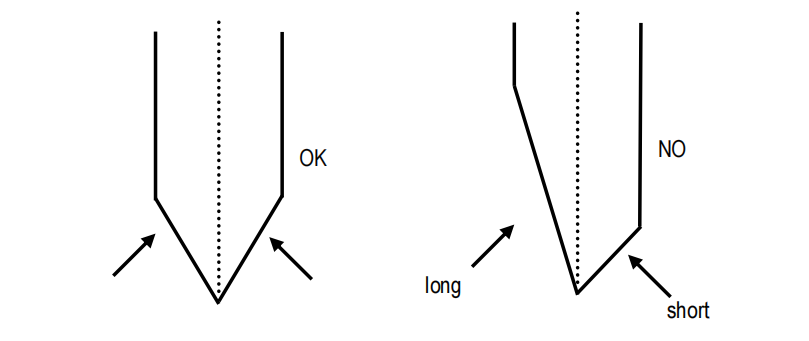

Connect the air pipe onto air cylinder and apply 0.5 – 0.8kgs pressure and check again whether the grinding stone contacting the knife edge is as per following drawing shown.

The contact area of knife edge(new blade) will be in between ½ to ⅓ area on the grinding stone.

Correction located at ⅓ of grind stone and use hand to push the air cylinder to touch the blade at ⅓ position shown as per drawing. Make sure both grinding wheels must be evenly contact with blade.

Step 7:

If the edge of new blade is exceeding or not within the range on the grinding stone, please repeat and readjust slightly heavier pressure as per step 4,5,6.

Step 8:

If the blade edge grinding shape to be became like the sketch

If the grinding on blade edges are not even, the board will not be clean, sharpening and cause burs and damage edges, too.

Step 9:

The recommended air pressure for using is within 0.5 – 0.8kgs. Too much pressure will cause the fast wearing out of blades.

Step 10:

On the slitter scorer computer system, it is usually set up at common grinding meters at 300 meters of slitting, then grinding the blade for 6 seconds. The operator should adjust the slitting length and grinding lasting time depends on the paper quality.

The blade grinding for the good quality of paper grade can be set at 500 meters slitting and then grinding for 6 seconds. Or, the blade grinding for the poor quality of paper grade can be set at 200 meters slitting and then grinding for 10 seconds.

Step 11:

When the corrugated boards are too soft which means too much moisture contains, glue not dried, the slitting quality will be impacted and shorten the blades usage life, too.

The oil cooling system for the blade grinding is recommended set at cooling for 15 seconds by every 30 minutes.

Always clean the oil brush/wool pad by compressed air every two days when the paper quality is 100% recycle paper and poor quality paper to insure the oil can be dip on the blade edges to cool the blades.

Change the wool pad once the cooling oil cannot be applied to the blade.

The recommended cooling oil is #30 or #40 lubrication oil for resistance of 150℃temperature.

Post time: Mar-08-2023